Press Releases

Visit of German Vice Chancellor

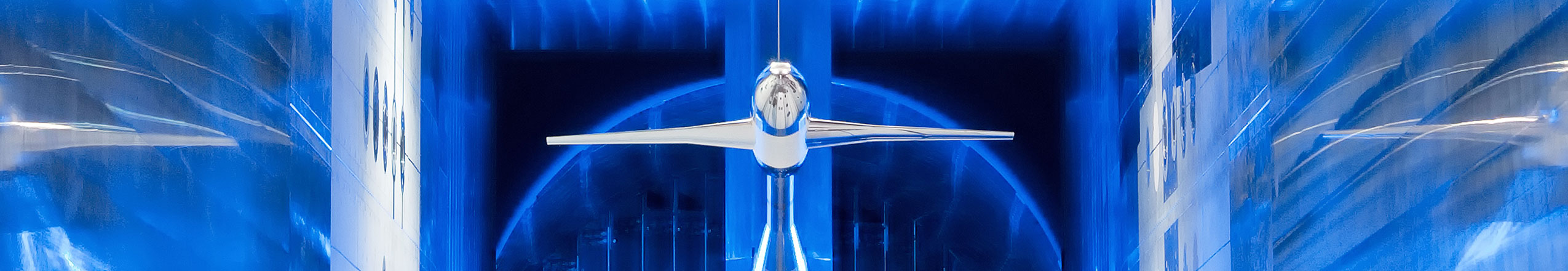

LTR: Prof. Henke, Prof. Dr. Wörner, Parliamentary State Secretary Hintze, Dr. Dietz, Minister Dr. Rösler at an A380 model in the ETW test section. Hi-Res [2.3MB]

During the DLR “German Aerospace Day” on 18 September 2011, the German Federal Minister of Economics and Technology, Vice Chancellor Dr. Philipp Rösler visited the European Transonic Windtunnel ETW in Cologne, Germany. Dr. Rösler and his delegation were especially interested in ETW’s role of supporting aircraft development from science to realisation.

ETW is the worldwide leading wind tunnel for testing aircraft at real flight conditions serving both research and industry. This facility is supported by the four associated nations Germany, France, UK and the Netherlands. Aircraft performance and their flight-envelope limits can be accurately predicted with unique quality at ETW much earlier than flight testing of a first prototype. As an industrial development tool ETW has contributed significantly to programmes such as Airbus A320, A350, A380 or Dassault Falcon 7X. Bridging the gap between laboratory and real-flight testing, ETW accelerates innovation from science to realisation, supports the competitiveness of European aeronautics and contributes to the development of sustainable air transport.

Identified by ACARE (Advisory Council for Aeronautics Research in Europe) as a strategic facility for Europe, ETW successfully serves as a research infrastructure in various European and national projects. Currently ETW is engaged in the EU funded FP7 ESWIRP programme aimed at optimising research infrastructures, to improve the quality of their simulation and to facilitate access to researchers and academia.

Completing his technical tour of the transonic wind tunnel, Dr. Rösler was impressed to be informed that the cryogenically operated ETW is able to provide data matching in-flight results of modern large transport aircraft with a unique accuracy of better than 99%.

ETW is an indispensable tool to safeguard the overall competitiveness of the European aeronautical industry in the long term. This high-tech facility enables scientists and industry to meet today´s and future needs for low-emission air transport by providing a unique capability in Europe to develop and validate innovative, sustainable solutions. In times of rising dynamic cycles of innovation, the investment in research and innovation is vital to sustain the opportunities for further technological development and the creation of high-grade jobs.

“The ETW is a significant strategic research facility for the European aeronautical industry. The special competences of this institution and its workforce are recognised worldwide. It is very important that the associated nations are working closely together to safeguard the future of the ETW", commented Dr. Rösler on his visit.

LTR: Dr. Dietz, Minister Dr. Rösler at an A380 model in the ETW test section. Hi-Res [1.2MB]

The present press release is also available as PDF here.

Background

ETW - Pushes the Limits

Wind tunnels, using scaled down aircraft models, are the major source of aerodynamic design data for new aircraft projects. Wind tunnels are indispensable tools for aerodynamic research and aircraft development; they complement and validate flow simulation methods on the most powerful computers.

ETW, the European Transonic Wind Tunnel, was designed and constructed by the four European countries France, Germany, United Kingdom and The Netherlands. It is operated based on a non-profit policy by the ETW GmbH, founded in 1988. Its location in Cologne, Germany, is right in the middle of Europe.

European researchers and engineers harness ETW’s capabilities for advancing aeronautical science into aircraft innovation by accessing real-flight conditions in this cutting edge ground-test laboratory.

ETW is the worldwide leading wind tunnel for testing aircraft at real flight conditions. Aircraft performance and their flight envelope limits can be accurately determined with unique quality at ETW long before flight testing of a first prototype. This enables significant reductions in the technical and economic risks associated with the development of new aircraft. Manufacturers from all over the world take advantage of the exceptional features of this high-tech facility enhancing the performance, economic viability, and environmental friendliness of their future aircraft.

ETW – Erweitert Horizonte

Aerodynamische Entwurfsdaten für neue Flugzeugprojekte werden zu einem großen Teil aus Windkanaluntersuchungen an maßstäblich verkleinerten Flugzeugmodellen gewonnen. Windkanäle sind unverzichtbare Werkzeuge sowohl für die Strömungsforschung als auch für die Flugzeugentwicklung; sie ergänzen und validieren Verfahren zur Strömungssimulation auf modernsten Hochleistungsrechnern.

Der Europäische Transschall-Windkanal ETW ist eine transnationale Forschungseinrichtung in Köln. Er wurde von den vier Staaten Frankreich, Deutschland, Großbritannien und den Niederlanden entwickelt und gebaut. Betrieben wird er von der ETW GmbH, die als eigenständiges Non-Profit-Unternehmen 1988 gegründet wurde.

Der ETW erlaubt europäischen Forschenden und Ingenieur:innen, tatsächliche Flugzustände unter Laborbedingungen am Boden darzustellen, um wissenschaftliche Erkenntnisse zu erarbeiten und in Luftfahrtinnovationen zu überführen.

Der ETW ist der weltweit führende Windkanal, in dem Luftfahrzeuge unter wirklichkeitsgetreuen Flugbedingungen getestet werden können. Lange bevor der erste Prototyp für einen Flugtest zur Verfügung steht, können im ETW die Leistungsfähigkeit und die Flugbereichsgrenzen eines Neuentwurfs genauestens und mit einzigartiger Qualität bestimmt werden. Dies reduziert erheblich die technischen und wirtschaftlichen Risiken, die mit der Entwicklung neuer Luftfahrzeuge verbunden sind. Hersteller aus aller Welt nutzen die außergewöhnlichen Möglichkeiten dieser Hightech-Einrichtung, um die Leistungsfähigkeit, die Wirtschaftlichkeit und die Umweltfreundlichkeit ihrer zukünftigen Produkte nachhaltig zu verbessern.