Press Releases

Onboarding the next generation of ETW’s Management

In the coming decades Aerospace Research and Development faces the challenge to transform our sector to sustainable aviation. Continuous improvement of aircraft performance by exploiting new materials, new technologies and through stretching the physical boundaries with even better integration, will play key roles in minimising aircraft energy consumption and climate impact. ETW has contributed to most recent major aircraft designs and we are prepared to continue supporting the aviation industry in achieving their highest ambitions by supplying best-in-class aerodynamic data at flight-relevant Reynolds numbers, aeroelastic effects of high aspect-ratio wings or the aircraft behaviour near the borders of the envelope. We remain committed to continuously improving the way we can best serve our clients; with cutting-edge measurement technology, innovative test procedures, and a dedicated and trustful client relationship. We are proud to announce that we are also preparing the Management crew for the challenges ahead.

In April, Andreas KLÖCKNER joined ETW to gradually take over from Peter GUNTERMANN as Manager Operations & Administration. In his previous position, Andreas has steered the aeronautics strategy and digitalization programme at DLR, Germany. Peter will be available for a few more years at a reduced intensity, ensuring a smooth and seamless transition with Andreas. In their shared role, they will continue to operate ETW as efficiently and effectively as our clients have come to expect. Using co-funded research projects, Peter and Andreas will further improve the procedures and technologies that ETW’s services are built upon.

In April, Andreas KLÖCKNER joined ETW to gradually take over from Peter GUNTERMANN as Manager Operations & Administration. In his previous position, Andreas has steered the aeronautics strategy and digitalization programme at DLR, Germany. Peter will be available for a few more years at a reduced intensity, ensuring a smooth and seamless transition with Andreas. In their shared role, they will continue to operate ETW as efficiently and effectively as our clients have come to expect. Using co-funded research projects, Peter and Andreas will further improve the procedures and technologies that ETW’s services are built upon.

In September, we will welcome Stuart GATES to join ETW and our Management crew as Manager Aerodynamics & Testing. Previously, Stuart has held the roles of Lead Technologist for Aerodynamics and Deputy Head of Technology for Whole Aircraft at ATI, U.K. Prior to this, Stuart was a principal engineer with Leonardo Helicopters, where he worked on both military and civil aircraft development projects. As our new Manager Aerodynamics & Testing, Stuart will be the primary point of contact for our clients and responsible for the promotion and further development of ETW’s services. Stuart will be available for all our clients to discuss current and emerging needs, so that we may further develop ETW’s capabilities accordingly.

In September, we will welcome Stuart GATES to join ETW and our Management crew as Manager Aerodynamics & Testing. Previously, Stuart has held the roles of Lead Technologist for Aerodynamics and Deputy Head of Technology for Whole Aircraft at ATI, U.K. Prior to this, Stuart was a principal engineer with Leonardo Helicopters, where he worked on both military and civil aircraft development projects. As our new Manager Aerodynamics & Testing, Stuart will be the primary point of contact for our clients and responsible for the promotion and further development of ETW’s services. Stuart will be available for all our clients to discuss current and emerging needs, so that we may further develop ETW’s capabilities accordingly.

With our new Management crew, we are eager to put all of our joint dedication into evolving ETW and its team to deliver the most reliable and accurate aero-testing environment that aerospace requires; to study, design and build sustainable and globally competitive air vehicles at the lowest risk possible. If you share our vision and passion, contact us to explore how we can jointly do even better!

Please find their contact details here.

Background

ETW - Pushes the Limits

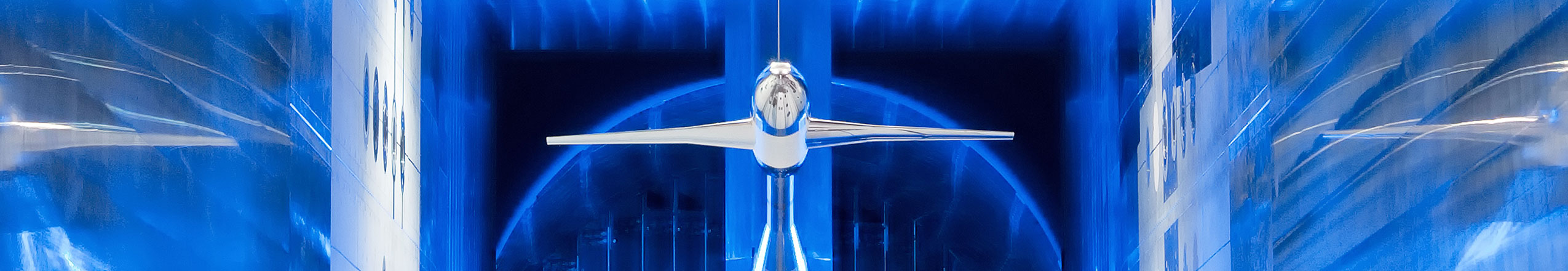

Wind tunnels, using scaled down aircraft models, are the major source of aerodynamic design data for new aircraft projects. Wind tunnels are indispensable tools for aerodynamic research and aircraft development; they complement and validate flow simulation methods on the most powerful computers.

ETW, the European Transonic Wind Tunnel, was designed and constructed by the four European countries France, Germany, United Kingdom and The Netherlands. It is operated based on a non-profit policy by the ETW GmbH, founded in 1988. Its location in Cologne, Germany, is right in the middle of Europe.

European researchers and engineers harness ETW’s capabilities for advancing aeronautical science into aircraft innovation by accessing real-flight conditions in this cutting edge ground-test laboratory.

ETW is the worldwide leading wind tunnel for testing aircraft at real flight conditions. Aircraft performance and their flight envelope limits can be accurately determined with unique quality at ETW long before flight testing of a first prototype. This enables significant reductions in the technical and economic risks associated with the development of new aircraft. Manufacturers from all over the world take advantage of the exceptional features of this high-tech facility enhancing the performance, economic viability, and environmental friendliness of their future aircraft.

ETW – Erweitert Horizonte

Aerodynamische Entwurfsdaten für neue Flugzeugprojekte werden zu einem großen Teil aus Windkanaluntersuchungen an maßstäblich verkleinerten Flugzeugmodellen gewonnen. Windkanäle sind unverzichtbare Werkzeuge sowohl für die Strömungsforschung als auch für die Flugzeugentwicklung; sie ergänzen und validieren Verfahren zur Strömungssimulation auf modernsten Hochleistungsrechnern.

Der Europäische Transschall-Windkanal ETW ist eine transnationale Forschungseinrichtung in Köln. Er wurde von den vier Staaten Frankreich, Deutschland, Großbritannien und den Niederlanden entwickelt und gebaut. Betrieben wird er von der ETW GmbH, die als eigenständiges Non-Profit-Unternehmen 1988 gegründet wurde.

Der ETW erlaubt europäischen Forschenden und Ingenieur:innen, tatsächliche Flugzustände unter Laborbedingungen am Boden darzustellen, um wissenschaftliche Erkenntnisse zu erarbeiten und in Luftfahrtinnovationen zu überführen.

Der ETW ist der weltweit führende Windkanal, in dem Luftfahrzeuge unter wirklichkeitsgetreuen Flugbedingungen getestet werden können. Lange bevor der erste Prototyp für einen Flugtest zur Verfügung steht, können im ETW die Leistungsfähigkeit und die Flugbereichsgrenzen eines Neuentwurfs genauestens und mit einzigartiger Qualität bestimmt werden. Dies reduziert erheblich die technischen und wirtschaftlichen Risiken, die mit der Entwicklung neuer Luftfahrzeuge verbunden sind. Hersteller aus aller Welt nutzen die außergewöhnlichen Möglichkeiten dieser Hightech-Einrichtung, um die Leistungsfähigkeit, die Wirtschaftlichkeit und die Umweltfreundlichkeit ihrer zukünftigen Produkte nachhaltig zu verbessern.