Press Releases

Disinfected Air for Aircraft Development

Safer working conditions in the world's leading aviation wind tunnel for realistic tests: ETW has added UVC modules to its existing building ventilation system. It eliminates up to 99.9% of all airborne germs, protecting its employees and users from viruses, bacteria and other pathogens.

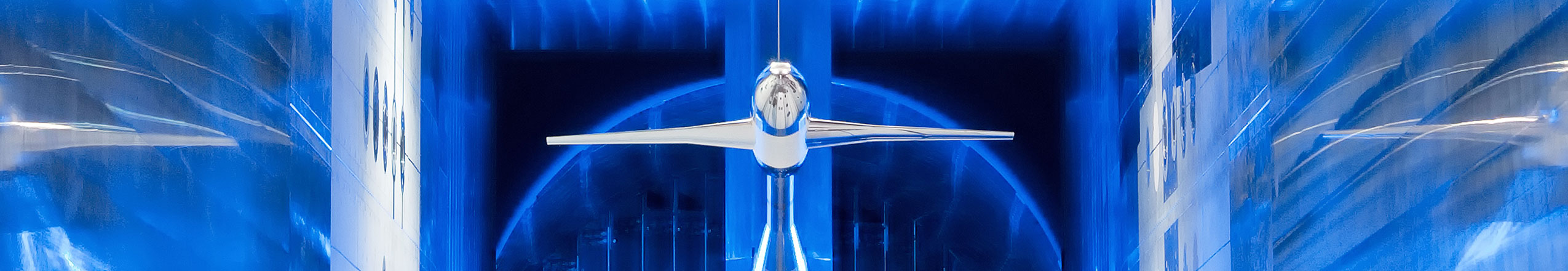

Precisely controlled flow conditions are the decisive factor at ETW: At speeds of up to Mach 1.35, the aircraft models are tested in the wind tunnel at realistic flight conditions. Here, the aerodynamics of very many models such as the Airbus A350 XWB or Dassault Falcon business jets have already been optimized, as the ETW is one of only two comparable facilities worldwide.

In the Corona pandemic, the market for aircraft development is facing major challenges. To increase the safety of R&D employees, an innovative UVC disinfection system has now been integrated in addition to the previous hygiene measures. An AirStream module from BÄRO Clean Air Technologies uses high-energy UVC radiation to eliminate viruses, bacteria and other airborne microorganisms directly in the air of the central ventilation system.

“In the pandemic, we are relying on an innovative solution made in Germany to provide additional protection to our colleagues and our international users in the control room from SARS-CoV-2 and other pathogens,” reports ETW Managing Director Dr. Guido Dietz. “Decisive factors for us were the seamless integration option into an existing system, the environmentally friendly and low-maintenance operation, and the decades of experience BÄRO has gained with UVC in disinfection.”

After installation, the system requires little maintenance. The illuminants have a service life of 9,000 hours and unlike other air purifiers, disinfection is not achieved with filters, which would then have to be disposed of as hazardous waste.

“We are delighted that with the ETW another very renowned institute relies on one of our UVC systems for air disinfection,” explains BÄRO Managing Director Dr. Sandra von Möller. “We can retrofit any ventilation system with UVC without the need for further measures. For every situation, we have safe and practical solutions to significantly reduce the health risk of many at-risk groups and everyone affected. With our Clean Air Technologies products, we help make work environments safer, as well as nursing homes, shopping areas and, after lockdown, schools and restaurant dining.”

Dr. Sandra von Möller, Managing Director of BÄRO Clean Air Technologies, inspects the installation of the new AirStream UVC disinfection system together with ETW Managing Director Dr. Guido Dietz. Hi-Res [14.9MB]. Photo: © BÄRO.

About BÄRO GmbH and its division Clean Air Technologies: The BÄRO success story began in 1967 with customized lighting for retail companies. Since 1994, BÄRO has also been on the market with Clean Air Technologies: with devices developed in-house, the room air is sterilized by encapsulated UVC light. In addition to ceiling and wall-mounted units, larger systems tailored to individual requirements are used for ventilation systems in buildings. BÄRO also develops solutions for exhaust air purification. From its headquarters in Leichlingen, Germany, BÄRO is active worldwide in selling its "Made in Germany" technology. The company employs around 150 people and is managed by Dr. Sandra von Möller and J. Manuel von Möller.

Background

ETW - Pushes the Limits

Wind tunnels, using scaled down aircraft models, are the major source of aerodynamic design data for new aircraft projects. Wind tunnels are indispensable tools for aerodynamic research and aircraft development; they complement and validate flow simulation methods on the most powerful computers.

ETW, the European Transonic Wind Tunnel, was designed and constructed by the four European countries France, Germany, United Kingdom and The Netherlands. It is operated based on a non-profit policy by the ETW GmbH, founded in 1988. Its location in Cologne, Germany, is right in the middle of Europe.

European researchers and engineers harness ETW’s capabilities for advancing aeronautical science into aircraft innovation by accessing real-flight conditions in this cutting edge ground-test laboratory.

ETW is the worldwide leading wind tunnel for testing aircraft at real flight conditions. Aircraft performance and their flight envelope limits can be accurately determined with unique quality at ETW long before flight testing of a first prototype. This enables significant reductions in the technical and economic risks associated with the development of new aircraft. Manufacturers from all over the world take advantage of the exceptional features of this high-tech facility enhancing the performance, economic viability, and environmental friendliness of their future aircraft.

ETW – Erweitert Horizonte

Aerodynamische Entwurfsdaten für neue Flugzeugprojekte werden zu einem großen Teil aus Windkanaluntersuchungen an maßstäblich verkleinerten Flugzeugmodellen gewonnen. Windkanäle sind unverzichtbare Werkzeuge sowohl für die Strömungsforschung als auch für die Flugzeugentwicklung; sie ergänzen und validieren Verfahren zur Strömungssimulation auf modernsten Hochleistungsrechnern.

Der Europäische Transschall-Windkanal ETW ist eine transnationale Forschungseinrichtung in Köln. Er wurde von den vier Staaten Frankreich, Deutschland, Großbritannien und den Niederlanden entwickelt und gebaut. Betrieben wird er von der ETW GmbH, die als eigenständiges Non-Profit-Unternehmen 1988 gegründet wurde.

Der ETW erlaubt europäischen Forschenden und Ingenieur:innen, tatsächliche Flugzustände unter Laborbedingungen am Boden darzustellen, um wissenschaftliche Erkenntnisse zu erarbeiten und in Luftfahrtinnovationen zu überführen.

Der ETW ist der weltweit führende Windkanal, in dem Luftfahrzeuge unter wirklichkeitsgetreuen Flugbedingungen getestet werden können. Lange bevor der erste Prototyp für einen Flugtest zur Verfügung steht, können im ETW die Leistungsfähigkeit und die Flugbereichsgrenzen eines Neuentwurfs genauestens und mit einzigartiger Qualität bestimmt werden. Dies reduziert erheblich die technischen und wirtschaftlichen Risiken, die mit der Entwicklung neuer Luftfahrzeuge verbunden sind. Hersteller aus aller Welt nutzen die außergewöhnlichen Möglichkeiten dieser Hightech-Einrichtung, um die Leistungsfähigkeit, die Wirtschaftlichkeit und die Umweltfreundlichkeit ihrer zukünftigen Produkte nachhaltig zu verbessern.